The formulation of biobased and biodegradable bioplastic compounds

Since 2011, our capacity for innovation has allowed us to actively participate in many national and European projects related to fishing, technical textiles, hygiene, and food packaging.

Formulation

Formulation is the key step in the development of a compound. It consists of the optimised mixing of raw materials and possibly fillers (mineral or vegetable) and/or additives.

The choice of raw materials (biodegradable bioplastics available on the market) is made according to the properties of the conventional material to be substituted, the transformation process, the duration of use of the product, and its targeted end of life (industrial composting, home composting, etc.). The integration and choice of fillers is also done taking into account all these specifications. The addition of additives makes it possible to provide specific properties: processability, homogeneity, UV resistance, colour, barrier properties, etc. to the material.

Thus, each formulation is specific and takes into account all of these parameters.

Compounding

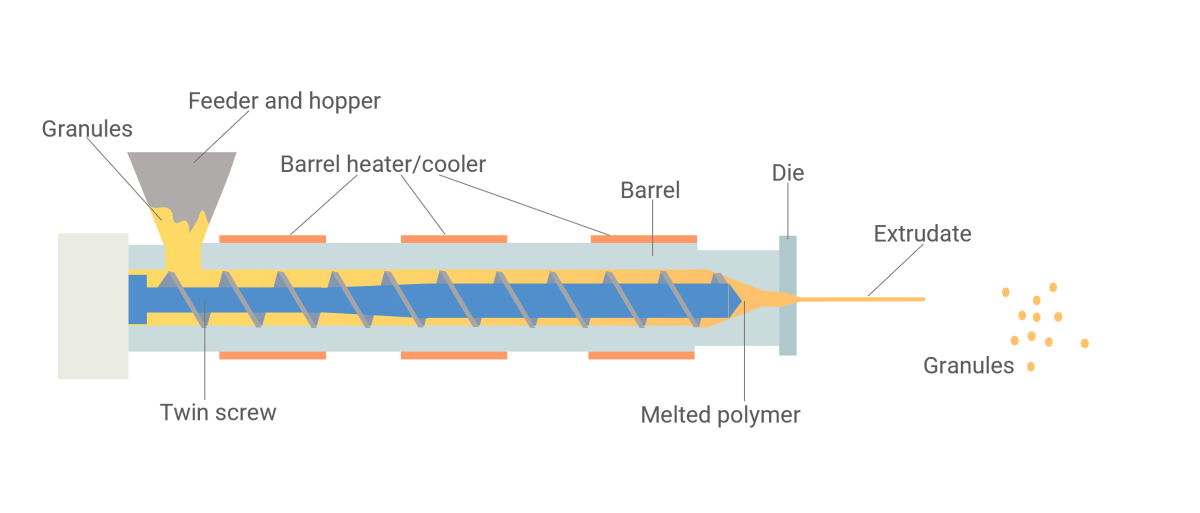

After selecting the constituents of the formulation, compounding can be carried out. This is an extrusion process in which the constituents are homogeneously mixed and melted, then carried by a mono- or twin-screw to the output die where a rod is obtained. After cooling, this rod is cut into pellets.

Our technology

In its pilot workshop, SeaBird is equipped with a complete and automated compounding line: dryers, mixer, dosers, twin-screw extruder, dryer, granulator. With a production rate ranging from 10 to 80 kg/h, we can contract produce small and medium quantities of compounds.

The granular compounds are packaged in 25 kg bags.

This pilot line allows us to produce our patented compounds, but also to develop new compounds as research and development in part of our DNA.

Our compounds can be transformed into finished or semi-finished products by the following processes:

- Injection moulding

- Extrusion spinning

- Profiles extrusion

- Mesh extrusion

- Cast extrusion

- Blown film extrusion

SeaBird has a laboratory dedicated to the research and development of bioplastic formulations, including a capillary rheometer for accurate rheology analysis of polymers.